Leading Lift Breakdown Repair Tips: Locating the Right Lift Servicing Companies

Leading Lift Breakdown Repair Tips: Locating the Right Lift Servicing Companies

Blog Article

Comprehensive Evaluation on Typical Concerns and Solutions in Lift Repair Service

In the realm of lift fixing, a precise exam of typical issues and their matching solutions is extremely important to making sure the seamless procedure and safety and security of these necessary vertical transport systems. From the troublesome troubles with lift doors to the detailed complexities of electrical breakdowns, a myriad of difficulties can pester lift capability (lift repair). As we look into the complexities of lift maintenance, a detailed understanding of these issues and the efficient techniques for fixing them emerges as a vital element of making certain optimal lift efficiency

Elevator Door Issues

One of one of the most common obstacles encountered in lift maintenance is attending to elevator door malfunctions. The smooth procedure of lift doors is critical for guest safety and effectiveness. A defective door can lead to hold-ups, aggravation, and also prospective threats.

Lift door issues can stem from numerous factors, such as malfunctioning door sensors, misaligned doors, worn-out rollers, or issues with the door driver device. These breakdowns can cause doors not opening or shutting effectively, obtaining stuck midway, and even shutting also swiftly, posing a danger to guests getting in or exiting the lift.

To attend to elevator door breakdowns efficiently, maintenance specialists have to carry out normal inspections, lube moving parts, change door timings, and change worn-out parts quickly. Furthermore, applying preventative upkeep timetables can assist identify and settle prospective door concerns prior to they escalate. By prioritizing elevator door maintenance and immediately resolving breakdowns, structure proprietors can make sure the safe and effective procedure of their lifts.

Electric Malfunctions

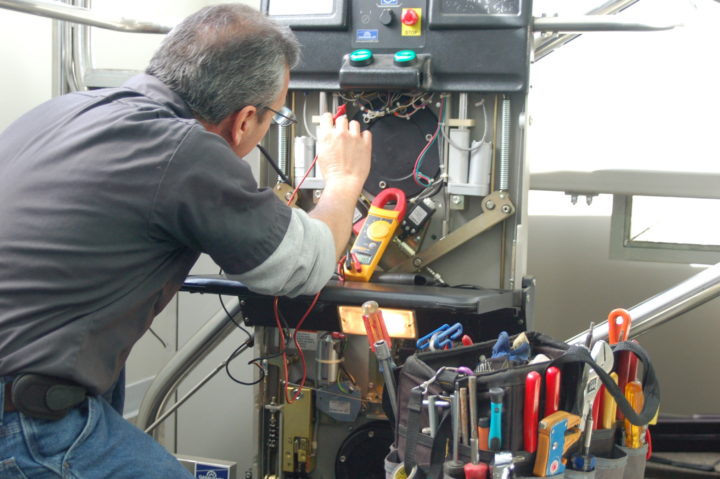

Attending to electric malfunctions in lifts needs detailed diagnostic assessments and specific troubleshooting methods to ensure the secure and trustworthy functioning of the lift system. Electric breakdowns can materialize in numerous means within a lift system, ranging from concerns with the control board, defective circuitry, power supply problems, to issues with sensing units and interlocks. When experiencing electric breakdowns, it is important for upkeep workers to follow an organized strategy. This consists of checking the power supply to the lift, inspecting electrical wiring for any kind of indications of damages or wear, and checking the capability of vital elements such as the control panel and emergency quit switch. Using analysis devices such as multimeters and circuit testers can aid in determining the source of the electrical malfunction precisely. Additionally, guaranteeing that all electric connections are secure and up to code is crucial in avoiding future malfunctions. By addressing electric problems immediately and effectively, lift service technicians can preserve the security and efficiency of lift operations.

Hydraulic System Issues

In addition, hydraulic pump failings can take content place because of issues such as overheating, excessive wear, or lack of proper upkeep. A malfunctioning pump can lead to the lift not having the ability to create sufficient hydraulic stress to operate efficiently. Routine evaluation, upkeep, and prompt replacement of hydraulic parts can stop these problems and ensure the smooth performance of the lift system. Appropriate training for upkeep employees on hydraulic system fixing and repair work can also assist in attending to these issues promptly and successfully.

Control System Problems

Control system malfunctions can interfere with the smooth operation of lift systems and present safety and security threats otherwise promptly attended to. These problems frequently stem from issues such as electrical failures, software program insects, or sensor breakdowns. When the control system falls short to communicate efficiently with the lift parts, it can cause unpredictable motions, unforeseen stops, or full closures. One common trouble is the misalignment of sensing units, leading to incorrect flooring progressing and door operations. Electric failures, including power rises or damaged electrical wiring, can likewise create the control system to breakdown.

To address control system glitches, lift repair service service technicians must perform extensive diagnostics to identify the origin of the concern. This might entail evaluating the electric links, calibrating sensing units, or reprogramming the control software application. Normal upkeep checks can help protect against these problems by identifying possible concerns prior to they rise (lift repair). By promptly resolving control system breakdowns, lift drivers can make sure the safety and reliability of their systems for passengers and prevent pricey downtime.

Safety And Security Includes Issues

In guaranteeing the optimal performance of lift systems, watchfulness in the direction of the integrity of safety functions ends up being critical following the recognition and resolution of control system glitches. Safety and security features in lifts are developed to prevent malfunctions, injuries, and accidents. Dealing with safety attribute concerns quickly can great site substantially lower the risk of helpful hints mishaps and enhance the general safety and security of lift operations.

Conclusion

To conclude, common issues in lift fixing consist of lift door concerns, electrical malfunctions, hydraulic system issues, control system glitches, and safety and security features worries. It is vital for maintenance teams to deal with these concerns quickly to make sure the risk-free and efficient operation of lifts. By carrying out correct upkeep protocols and normal examinations, these problems can be determined and dealt with effectively to stop any type of disruptions in lift feature.

In guaranteeing the optimal capability of lift systems, watchfulness towards the honesty of security attributes comes to be extremely important following the recognition and resolution of control system problems - platform lift dimensions.In verdict, usual problems in lift repair service consist of lift door issues, electrical breakdowns, hydraulic system problems, control system glitches, and safety and security attributes concerns

Report this page